説明

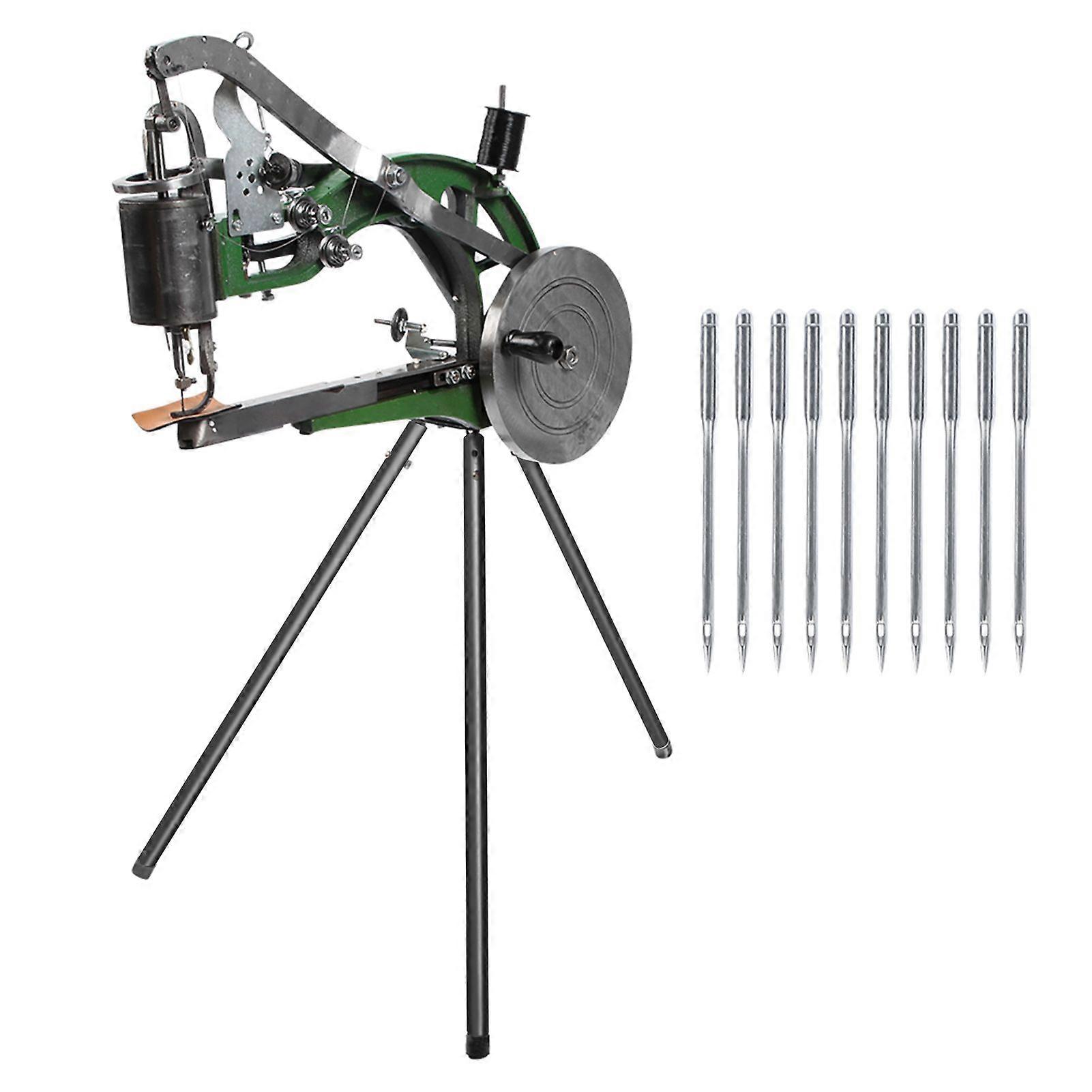

Features:1. It is a small shoe repair machine that can be used to sew shoes of different materials with nylon or cotton thread. 2. Suitable for repairing shoes, rubber shoes, leather shoes, sports shoes, high heels, raincoats, travel bags, leather bags, cloth, pants and other leather goods3. This machine can be used with nylon thread and cotton thread, and the sewing thickness is 5mm.4. The distance between the needle is adjustable and the width is approximately 6 mm.5. Simple structure and high efficiency, it is popular in shoemakerSpecification:Condition: Brand NewMaterial: MetalColor: As picture show Package List:1 x Manual Shoe Repair Machine1 x Bobbin1 x Tripod Bracket1 x Needle1 x Nylon Coil1 x Small Connecting Rod1 x GuideNote: 1. The screw, bobbin and wire rod of the machine are already installed on the machine. You do not need to install it yourself. The guide and coil need to be installed by yourself.2. Please note that the new type and old type of this product will be sent randomly, and make sure you will not mind before ordering.3.The tightness should be adjusted before use, otherwise the cotton thread is easy to break.Use and Maintenance: The active part of the shoe-removing machine needs to be refueled once a day to ensure that the machine runs lightly, without noise, improving work efficiency and prolonging service life.Preparation before operation: Pull up the presser foot to avoid friction between the presser foot and the needle plate. Check the tightening of the fixing screws of each part. Add grease to each part of the fueling point and shake the guide plate without any click.Threading and Leads:Take the shuttle and the bobbin, swing the guide, raise the needle to the highest position, take the shuttle with the tweezers, lift and push the upper needle plate, and take the shuttle with the tweezers.Bobbin Winding:Pull down the winding machine, pull out the thread around the bobbin and insert it into the bobbin for several weeks. Shake the guide to be wrapped around the bobbin. Pull the bobbin and pull the bobbin thread to pass the bobbin thread. The colleague will insert the bobbin into the shuttle, and then thread the thread to the upper thread hole to pull the line to move. The position of the shuttle is the hand-guided guide. When the needle is about to rise, the tail should be aligned with the needle groove, and the thread end should be pulled out 2-3 inches long. Press the needle plate and then close the upper needle plate.Wear the Upper Thread:Shake the guide, raise the needle to the highest position, and lower the presser foot. Pull the wire end in the online roll, pass through the middle shaft wrap spring, pass the wire clamp and the wire frame, pass through the wire spring and the wire pick, enter the needle bar hole, and then pull the wire through the pin hole to pull out the wire head 2-3 Inch long left hand side of the line thread head (not too tight), use the right hand to shake the guide plate, put the needle belt line through the needle board hole to pull out the bottom line, and the bottom line together make the machine presser foot gap left rear.The relationship between the surface limit and the quality of the seam:The identification of the stitches, the bottom line pressure is adjusted, and the upper thread is tightened to loosen the line nut. When the use time is too long, the bottom line will appear too fast. At this time, the thread can be threaded or the heart can be changed, and the bottom line will be taken. The rod seat fixing screw is relaxed, the needle picking rod is pushed backwards, and then the bobbin rotation is checked whether it is flexible. Sanding with sandpaper and tightening the adjustment of the stitch length of the crimping nut, the stitch length must be adjusted due to different sewing materials, and the stitch length is long. In this case, it is only necessary to loosen the needle pitch screw, and when the stitch length is short, and vice versa, it is sufficient. When the seam is thickened, the pressure must be increased. At this time, the presser spring nut can be tightened to increase the tension of the tension spring, which increases the pressure of the presser foot, and vice versa.Handing and unloading of the needle and the matching of the sewing material:Turn the guide plate to raise the needle bar to the highest position. Loosen the needle collet screw, remove the old needle, insert the new needle flat into the groove of the needle bar, when the needle touches the needle positioning position at the bottom of the groove, and then tighten the screw. Just fine.Needle and sewing material:Generally, the 16th needle is used to sew various kinds of rubber shoes and edging shoes, etc., and the 14-16th needle is used for thinner, and the 18th needle is used when sewing various leather shoes and canvas.Adjustment of the position of the Soto:When the shuttle is disconnected, the tail of the shuttle must be aligned with the needle slot. The difference is

-

ブランド:

Unbranded

-

カテゴリー:

ミシン

-

Fruugo ID:

426055645-894829772

-

EAN:

7313854311356