説明

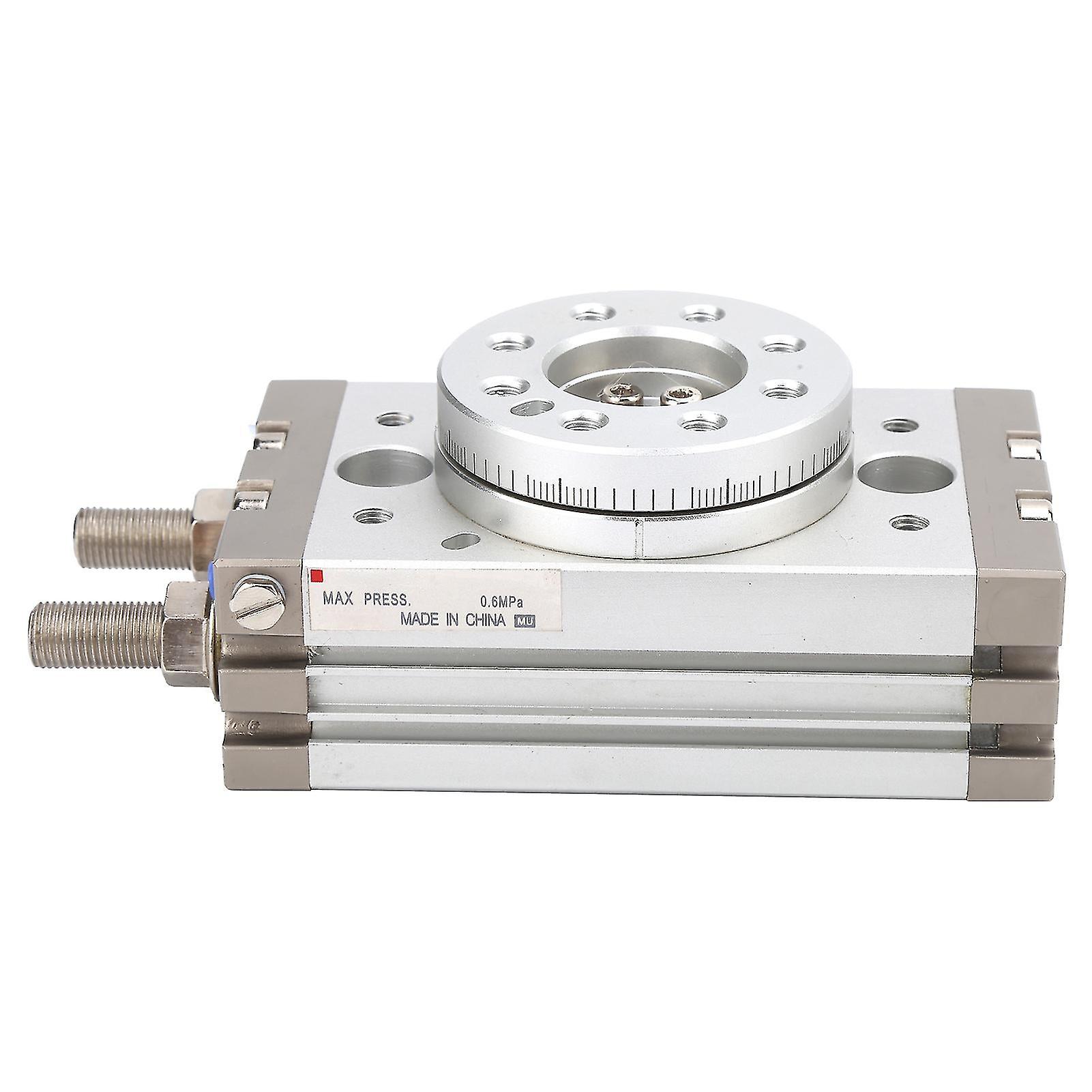

1This pneumatic air cylinder is rotating table type, easy to work and install, improve work efficiency 2Adopt roller bearing design, load is 3 to 4 times larger than for CRQ series, very practical 3Smooth and accurate swing, built-in magnetic ring, so that magnetic switch can be installed 4Alloy steel material, posse high strength, high toughness, wear resistance, corrosion resistance 5Action type is double action, the angle adjustment range is 0-190, which is very flexible, and the bore is 10mm

Item Type: Pneumatic Air Cylinder

Model: MSQB10A

Bore Diameter: Approx. 10mm / 0.4in

Medium: Air

Action Type: Double action

Angle Adjustment Range: 0-190

Connection Pipe Diameter: M5x0.8

1. Type Selection:According to the working requirements and conditions, the correct type of cylinder is selected. Requires that the cylinder reaches the end of the stroke without impact and impact noise. Buffer cylinders should be selected; for light weight, light cylinders should be selected; for narrow installation space and short strokes, thin cylinders are optional; for lateral loads, cylinders with guide rods are optional; requirements For high braking accuracy, lock cylinders should be selected; piston rods are not allowed to rotate, and cylinders with non-rotating rod function can be selected; heat-resistant cylinders should be used in high temperature environments; corrosion-resistant cylinders should be used in corrosive environments. In harsh environments such as dust, it is necessary to install a dust cover on the extension end of the piston rod. When no pollution is required, oil-free or oil-free lubrication cylinders should be selected.

2. Installation Form:Determined according to factors such as installation location and purpose of use. In general, a fixed cylinder is used. When it is necessary to continuously rotate with the working mechanism (such as lathes, grinders, etc.), rotary cylinders should be used. When the piston rod is required to move in an arc in addition to linear motion, shaft pin cylinders are used. When there are special requirements, the corresponding special cylinder should be selected.

3. The Size of the Force:That is, the choice of bore. Determine the thrust and pulling force output by the cylinder according to the size of the load force. Generally, the force of the cylinder is required to balance the conditions of the external load theory, and different load rates are selected according to different speeds, so that the output force of the cylinder has a little margin. If the cylinder diameter is too small, the output power is not enough, but the cylinder diameter is too large, making the equipment bulky, increasing the cost, increasing the gas consumption, and wasting energy. In the fixture design, the force expansion mechanism should be used as much as possible to reduce the external size of the cylinder.

4. Piston Stroke:It is related to the use occasion and the stroke of the mechanism, but generally the full stroke is not selected to prevent the piston and the cylinder head from colliding. If it is used for clamping mechanism, etc., a margin of 10-20mm should be added according to the calculated stroke.

5. The Movement Speed of the Piston:Mainly Depends On The Input Compressed Air Flow Rate of The cylinder, the size of the cylinder's intake and exhaust ports and the size of the inner diameter of the duct.

-

Fruugo ID:

203605313-432939418

-

EAN:

889615154564