説明

Feature:

1. When you fit the wire screw set in the screw hole of the workpiece of aluminum alloy and other materials, the insert can form a high‑strength, wear‑resistant, high‑accuracy standard female thread

2. Repairing the threaded hole in a cost‑effective manner. Threaded insert can be used as a repair method when a thread error occurs or a damaged female threaded hole is repaired

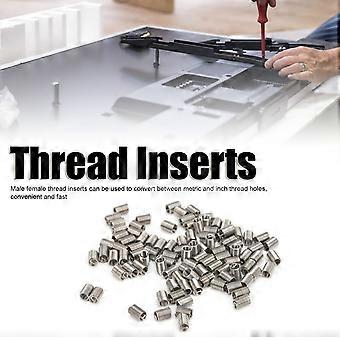

3. Male female thread inserts can be used to convert between metric and inch thread holes, convenient and fast

4. Using high‑strength, high‑accuracy diamond‑shaped cross‑section steel wire. Wire thread inserts are also called threaded sheaths, stainless steel threaded sleeves, wire sleeves, which is a new type of female threaded fasteners

5. Used to low‑strength engineering materials such as aluminum alloy, zinc alloy, alloy, copper, plastic, engineering plastics, etc., which can significantly improve thread strength and wear resistance

Specification:

Item Type: Thread Inserts

Material: SUS304

Model: M2.5x0.45

Thread Specification: M2.5x0.45 (mm)

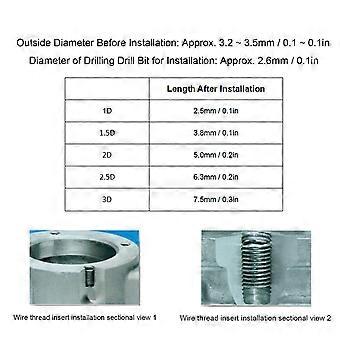

Outside Diameter Before Installation: Approx. 3.2 ~ 3.5mm / 0.1 ~ 0.1in

Diameter of Drilling Drill Bit for Installation: Approx. 2.6mm / 0.1in1D/1.5D/2D/2.5D/3D:

Length After Installation: Approx. 2.5mm / 0.1in3.8mm / 0.1in

5.0mm / 0.2in

6.3mm / 0.2in

7.5mm / 0.3inNumber of Turns Before Installation: 2.6/5.9/8.2/10.5/12.8Thread Protective Sleeve Model Specification Description: For Example: M3x0.5X1.5D, which means that after the screw set is completed, the female thread is M3, the pitch is 0.5, and the length is 1.5D (length refers to 1.5 times the diameter, that is, 1.5x3=4.5mm ), the length here refers to the length after installation.How to Use:

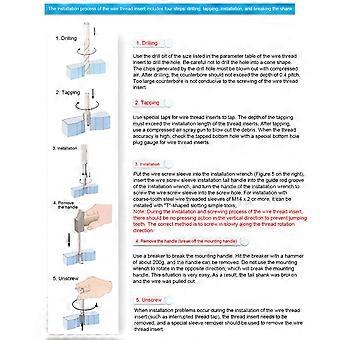

1. Drilling

Use the drill bit of the size listed in the parameter table of the wire thread insert to drill the hole. Be careful not to drill the hole into a cone shape. The chips generated by the drill hole must be blown out with compressed air. After drilling, the counterbore should not exceed the depth of 0.4 pitch. Too large counterbore is not conducive to the screwing of the wire thread insert.

2. Tapping

3. Installation

Put the wire screw sleeve into the installation wrench (figure 5 on the right), insert the wire screw sleeve installation tail handle into the guide rod groove of the installation wrench, and turn the handle of the installation wrench to screw the wire screw sleeve into the screw hole. For installation of M14x2 or more phase thread thread inserts, you can use the "T" type slotting simple tool to install; Note: During the installation and screwing process of the thread inserts, there should be no pressing in the vertical direction to prevent jumping teeth. The correct method is slowly screw in the direction of thread rotation.

4. Remove the handle (break off the mounting handle)

Use a breaker to break the mounting handle. Use about 200g of coconut to hit the breaker instantly, and the handle can be removed. Do not use the mounting wrench to rotate in the opposite direction. Do not break the mounting handle. This situation is very easy. As a result, the tail shank was broken and the wire was pulled out.

5. Unscrew

When installation problems occur during the installation of the wire thread insert (such as jumping teeth), the thread insert needs to be removed, and a special sleeve remover should be used to remove the wire thread insert. .

Package List:

100 x Thread Inserts

-

Fruugo ID:

334019443-736245107

-

EAN:

7695727364899

製品安全情報

以下に概説するこの製品に固有の製品安全性情報を参照してください。

以下の情報は、この製品を販売する独立したサードパーティ小売業者によって提供されています。

製品安全ラベル

安全上の警告:

Warning: Please read the product instructions carefully before use to ensure correct use.

シリアルナンバー:

7695727364899