説明

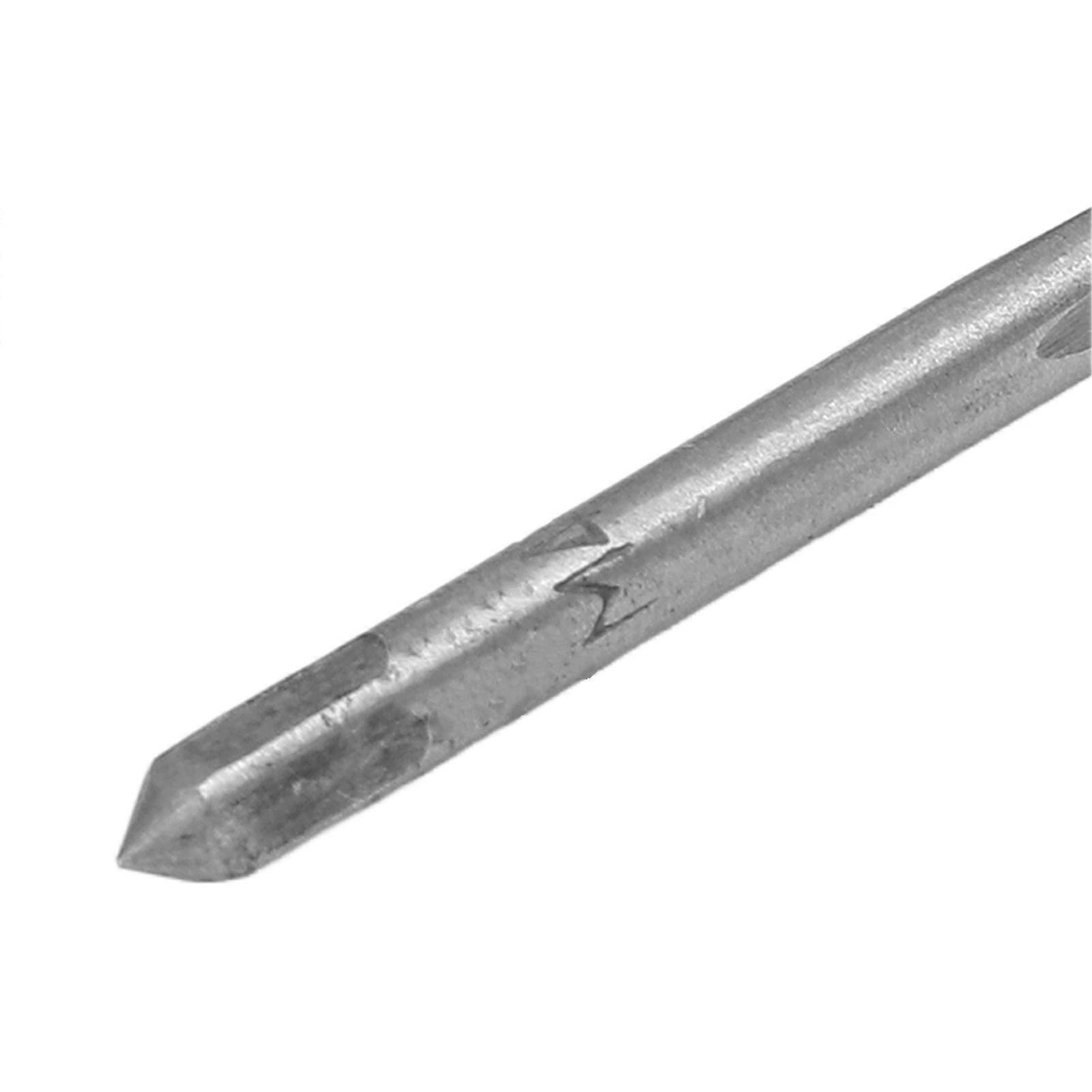

2Pcs/Set Metric Machine Tap High Speed Steel 3 Straight Flutes Screw Thread Tapping ToolM3x0.5

Feature:

1. Premium Material: High‑speed steel taps are with high hardness and wear resistance. Uncoated taps have only a basic substrate without any additional coatings, and fit a wide range of applications.

2. Function: There are a total of two taps to facilitate the alignment of the tap and the tapping hole to ensure that the tap and the hole are perpendicular to each other and tapping smoothly. It also has a smoothing effect on the thread (removes burrs).

3. Standard Thread: Standard metric thread design, clear and tidy, provide rapid chip removal for efficient threading. Can make new threads or re‑thread damaged or jammed threads.

4. Wide Application: Suitable for most metals, iron plate, copper, zinc, alloy steel, abrasive steel, A3 steel, stainless steel, etc. Appropriate addition of coolant (e.g. water) can extend the service life when tapping.

5. Applicable Industry: The mini metric taps are mainly used for clocks, watches, low hardness wood and soft metal hole processing. Mainly used for hand use, tapping the vast majority of materials in through holed conditions.

Specification:

Item Type: Hand Thread TapSystem: Metric

Number Of Threads: 3

Thread Tolerance Grade: 0.014

Through Hole/Blind Hole: Through Hole

Material: High speed steel

Tap Style: Straight groove

Thread Code: Standard thread

Application: Suitable for thick steel, rubber, aluminum, copper, and wood.

How to use: 1. There are 2 in a set, and it can also be divided into first tap and second tap.2. The function of the first tap: The front part of the first tap has a taper, which is smooth and has no thread (very shallow), so that it is convenient for the tap to align with the tapping hole to ensure that the tap is perpendicular to the hole and tapping smoothly. 3. The function of the second tap: In addition to processing the margin of the first tap to meet the standard, it also plays a role in trimming the thread (removing burrs). For blind hole threads, they can be tapped to the bottom It can be simply said that the first tap is rough machining, and the second tap is fine machining.4. Generally, the side of the workpiece that needs to be tapped should be placed in a horizontal or vertical position. In this way, when tapping the thread, it is easier to judge and maintain the direction of the tap perpendicular to the base surface of the workpiece thread.5. When starting to tap the thread, try to position the tap as much as possible, then press the axis of the tap with one hand, and gently rotate the hinge with the other hand. When the tap rotates 1‑2 turns, observe from the front or side whether the tap is perpendicular to the thread base surface of the workpiece. If necessary, use a square to correct it. Generally, after tapping 3‑4 turns of the thread, the direction of the tap is basically determined. If you start tapping the thread incorrectly, you can unscrew the tap, correct it with the second taper, and then tap the thread with the first taper. When the cutting part of the tap enters the workpiece, no axial force is required, and the thread is naturally screwed in. Can.6. When tapping the thread, each time the hinge screw is rotated, the screw advancement of the tap should not be too much. Generally, it is advisable to advance 1/2-1 rotation each time, and the screwing of the tap below M5 shall not exceed 1/2 rotation at a time; When tapping fine threads or threads with higher precision requirements, the feed amount should be appropriately reduced each time; the speed of tapping cast iron can be appropriately faster than that of tapping steel. After each screwing, the reversal is about The stroke of screwing is 1/2 of the stroke; when tapping a deeper thread, the stroke of the rotation is larger, and it needs to be reciprocated several times to break the chips, which is conducive to chip removal, and reduces the phenomenon of chip sticking on the cutting edge to maintain Sharp cutting edge; At the same time, the cutting fluid can smoothly enter the cutting part, which plays a role of cooling and lubrication.

7. When rotating the hinge lever, the operator's two hands must be balanced. Do not use too much force and shake left and right, otherwise it is easy to tear the thread profile and cause the threaded hole to expand and appear taper. .

Package List:

2 x

Straight Flute Tap1 x Storage Box

-

Fruugo ID:

386283032-830007289

-

EAN:

7590917500456