説明

Product features and key benefits

Strong clamping force designed for heavy cutting: supports material removal rates while keeping the workpiece stable and reducing rework.

Two control modes for flexible integration: compatible with air cylinder actuation or manual screw fixing to suit automated CNC cells or manual setups.

precision doublesided clamping: singlesided stroke 5 mm, surface ground to Ra < 0.4 and roundness < 0.8 for consistent, repeatable positioning.

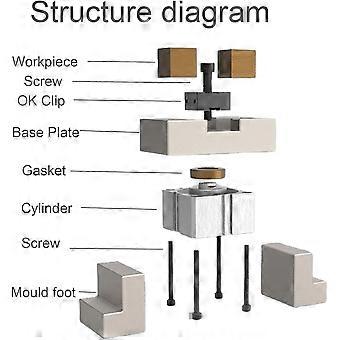

Robust cam clamp design: builtin spring for reliable , a main body designed to resist cracking, and a side threaded hole that accepts a semicircular jaw for secure holding of cylindrical parts.

Efficient layout and operation: clamps can be used side by side to clamp multiple points quickly, saving setup time and improving workflow.

Technical specifications and functions

Control modes: pneumatic (air cylinder) or manual screw fixing.

Doublesided clamp stroke: 5 mm (singlesided).

Surface finish: Ra < 0.4 (surface grinding).

Roundness tolerance: < 0.8.

Cam clamp features: internal spring, side threaded hole for semicircular jaw attachment, suitable for cylindrical workpieces.

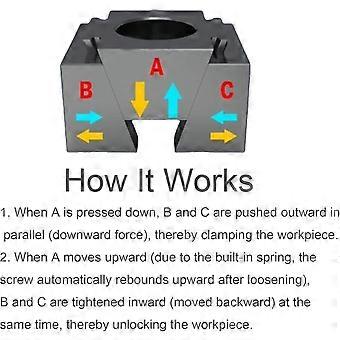

Operating principle (screw clamp): downward wedge movement forces the clamp to squeeze and expand outward to lock the workpiece; upward wedge movement relaxes and contracts inward to release the workpiece.

Why this product solves common workshop problems

Reduces vibration and workpiece movement during heavy cutting by providing a clamping force, improving surface finish and dimensional accuracy.

Simplifies integration into both automated and manual processes through dual control mode compatibility.

Delivers precise, repeatable clamping with tight surface and roundness tolerances to minimize fixture adjustment and inspection time.

Speed up multistation setups by allowing sidebyside placement and modular jaw attachment for different part geometries.

Practical applications / use scenarios

1) CNC milling of steel shafts: Use the cam clamp with a semicircular jaw to secure cylindrical shafts for heavy roughing cuts, maintaining concentricity while enabling efficient successive operations.

2) precision part production: Use doublesided clamps with 5 mm stroke and fine surface finish for fixtures that require repeatable clamping and tight runout tolerances in medium to volume machining.

3) Hybrid cells and manual setups: Select pneumatic actuation for automated cells or the manual screw option for smallbatch jobs or setups without pneumatic supply, enabling consistent clamping across different configurations.

Operation and installation notes

Choose pneumatic control when fast, repeatable actuation is required; use manual screw fixing when pneumatics are not available or for fine adjustment.

For cylindrical parts, install the semicircular jaw into the side threaded hole of the cam clamp to improve contact area and reduce deformation.

When using multiple clamps side by side, align wedge surfaces and mounting positions to ensure even clamping force distribution.

This set of clamping components provides heavyduty holding power, precise repeatability, and flexible control options for CNC and manual machining environments, while supporting efficient, multipoint fixture layouts.

-

ブランド:

Unbranded

-

カテゴリー:

クランプ

-

Fruugo ID:

440993152-925523764

-

EAN:

6221783007169