説明

Key benefits and features

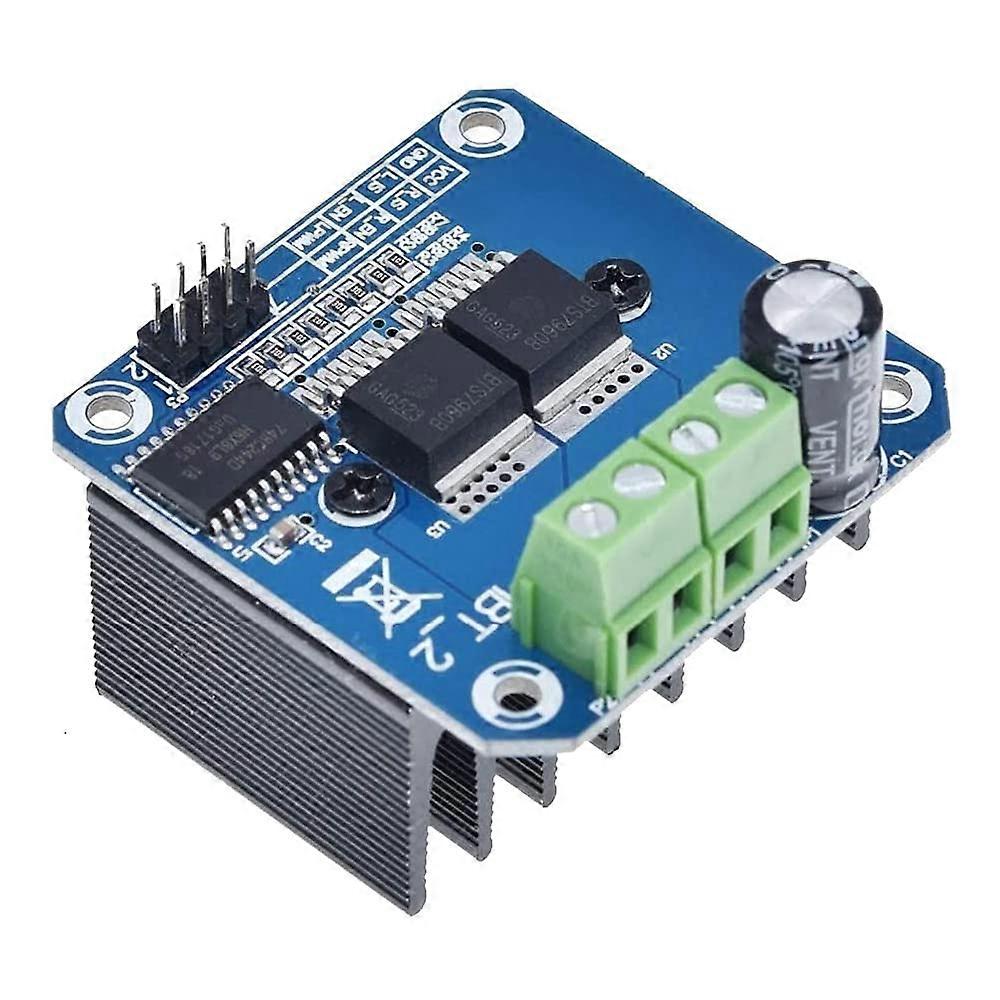

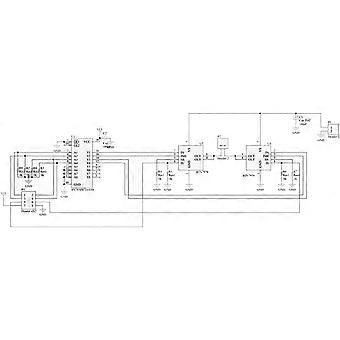

MCU protection through isolation: Provides 1.5V isolation with the MCU, effectively safeguarding the MCU from motor driver activity. Includes a 5V power indicator on the board to confirm operation.

Clear output status and heat management: Displays voltage indication at the motor driver output end. The design supports attaching a heatsink via soldering, aiding thermal management during operation.

Flexible motor control and fault signaling: Enables forward and reverse motor drive. Supports two PWM input channels with up to 25 kHz switching frequency. Includes an error signal output for fault indication.

Simple, fourwire MCU interface: Requires only four lines from the MCU to the driver module: GND, 5V, PWM1, PWM2. The isolation chip is powered by a 5V supply, which can be shared with the MCU 5V, simplifying power wiring and integration.

What makes it stand out

Protection without complexity: The module integrates isolation to protect the MCU while remaining easy to wire with a minimal fourline interface.

Visual status and thermal flexibility: Builtin voltage indication at the motor driver output and the option to fit a heatsink provide practical visibility and thermal management for compact setups.

Efficient PWM control: Two independent PWM inputs allow flexible motor drive configurations with a maximum frequency of 25 kHz, supporting fast and smooth motor control.

Easy integration with existing 5V systems: The 5V power supply for the isolation chip can share the MCU supply, reducing the number of required power rails and simplifying power design.

Compatibility and practical use

Works with standard 5V MCU systems that can provide PWM1 and PWM2 signals and share GND and Vcc with the driver.

Suitable for compact motor control in embedded projects where MCU isolation is desired and a simple fourwire control scheme is preferred.

Useful in education, hobby robotics, small automation, and prototyping environments where clear status indication and thermal management are beneficial.

23 practical use scenarios

Scenario 1: Small educational robotics project

Use a 5V microcontroller to send PWM signals on PWM1 and PWM2 to drive a DC motor. The MCU is isolated from the motor driver, reducing noise and protecting the controller. The 5V indicator helps verify power, and the option to solder a heatsink aids in heat management during longer runs.

Scenario 2: Compact automated subsystem

Integrate with a microcontroller to control a single motor in a compact automation module. The fourwire interface (GND, 5V, PWM1, PWM2) keeps wiring minimal, while the isolation and fault output provide a safe and maintainable setup for an automated workflow.

Scenario 3: Laboratory motor control experiments

Use the dual PWM inputs to experiment with forward and reverse motor operation and observe the fault signaling behavior. The motor output voltage indication assists in monitoring and debugging under test conditions, with an optional heatsink for thermal stability.

Notes

The description preserves the original functions: MCU isolation, 5V power indication, motor driver output voltage indication, heatsink compatibility, bidirectional motor control with two PWM inputs up to 25 kHz, and a fault/error signal output, plus a simple fourline MCU interface and shared 5V power supply option.

-

Fruugo ID:

432184506-907655925

-

EAN:

6483439734687