説明

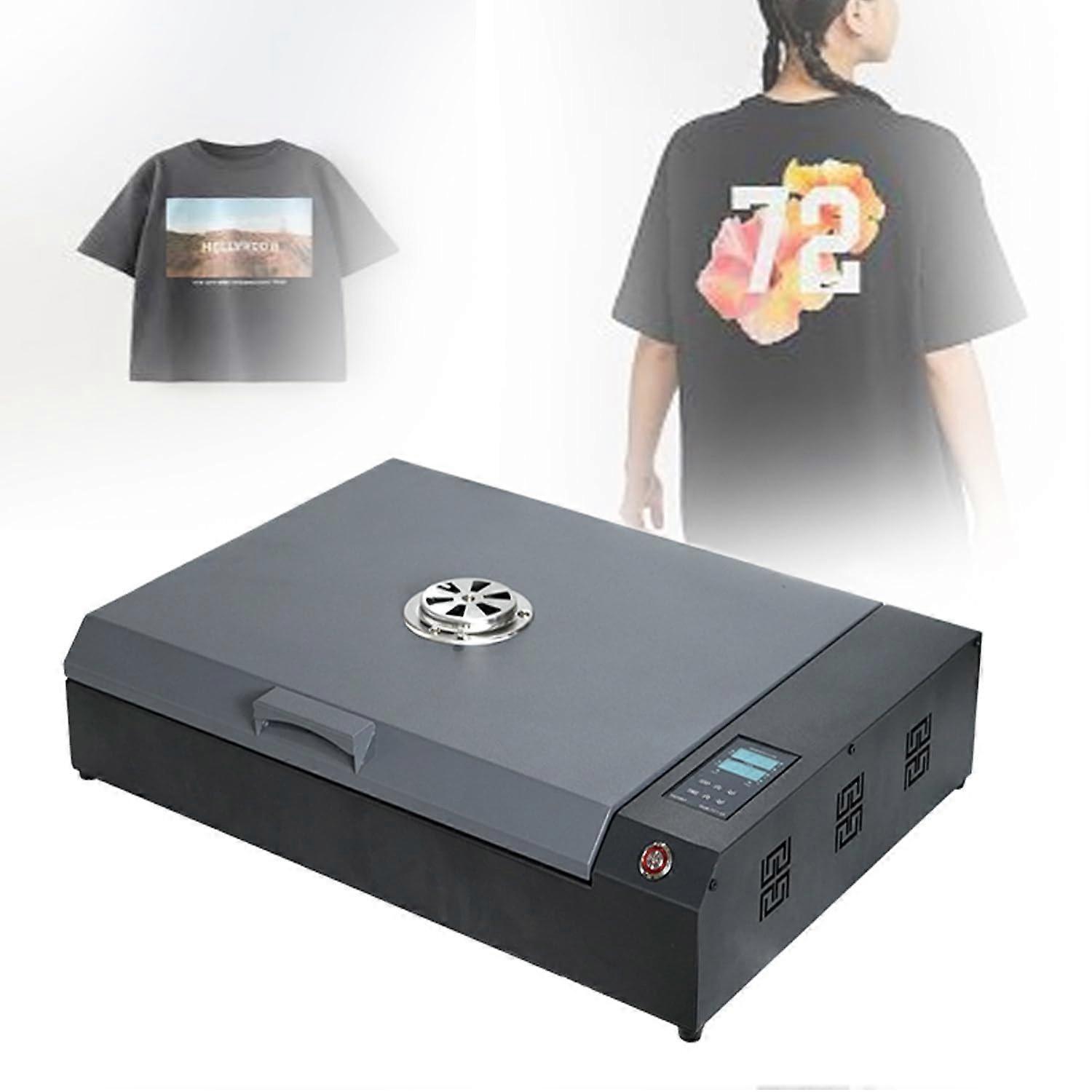

DTF Curing Oven with Dual Heating Plates PID Control for TShirt and Hat Printing

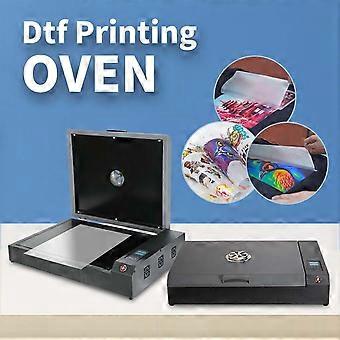

DTF Dual Heating Drying Oven — Precise curing for consistent transfers

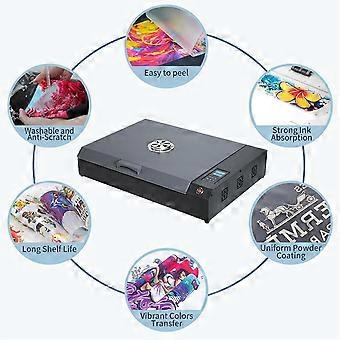

Key benefits

Even, stable heating for reliable transfers: Dual aluminum heating plates and a precision PID temperature control chip keep temperature within plus or minus 1 degree C, reducing color distortion and film stripping and delivering clearer, longerlasting transfers.

Fast, repeatable operation: Powerful 930W heating and a digital timer let you run consistent cycles with minimal monitoring.

Safer handling and longer run time: Allmetal antiscalding drawer, adjustable bracket, and three protection features (automatic shutdown on overheating, leakage protection, antiscalding design) allow continuous operation for up to 8 hours with less risk of accidental burns while changing materials.

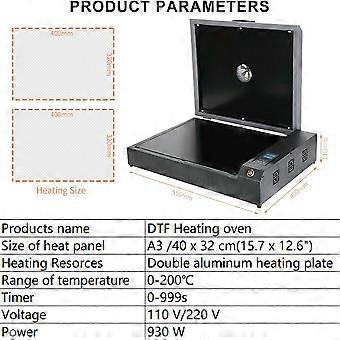

Specifications

Power: 930W

Heating plate size: 40 x 32 cm (15.7 x 12.6 inches)

Heating source: Dual aluminum heating plates

Temperature range: 0 to 200 degrees C

Temperature control: Builtin PID chip, fluctuation ±1 degree C, LED digital display for realtime monitoring

Timer range: 0 to 999 seconds

Packaging size: 66 x 51 x 25 cm (26 x 20 x 9.8 inches)

Weight: 11 kg (25 pounds)

What makes it stand out

Dual heating plates and PID control ensure uniform temperature across the heating surface, which prevents uneven curing that can cause film lifting or color shifts.

LED digital readout and precise timer provide repeatable settings for batch work.

Drawertype tray and adjustable bracket make loading and unloading transfers quick and reduce contact with hot surfaces.

Typical use scenarios

Apparel production: Cure DTF transfers onto Tshirts, hoodies, and other flat garments where uniform heat and consistent time produce reliable adhesion and color accuracy.

Smallbatch custom printing: Ideal for studios or home businesses finishing small runs of custom transfers with repeatable results.

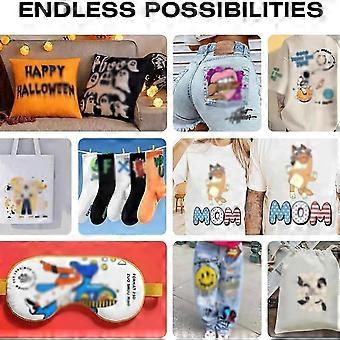

Accessories and fabric goods: Use for bags, pillow covers, and other textile items that fit the 40 x 32 cm heating area.

How to use (recommended)

1. Set oven temperature to 140 degrees C and timer to 360 seconds as a starting point. Adjust based on material and transfer thickness.

2. Allow oven to reach the set temperature. Monitor the LED display for realtime readings.

3. After applying the DTF transfer to the substrate, remove the release liner as required, place the PET film or transfer into the drawer tray, and start the timer.

4. When the cycle finishes the oven will signal completion. Remove the tray using the drawer and adjustable bracket to avoid contact with hot surfaces.

Compatibility and performance notes

Designed for use with DTF transfers and compatible heattransfer workflows that fit the 40 x 32 cm plate.

Temperature and time settings may need adjustment for different substrates, ink densities, or film types.

Continuous operation capability supports extended production runs; follow recommended maintenance and cooling intervals as needed for longterm reliability.

This DTF drying oven combines precise temperature control, consistent heating, and practical safety features to improve transfer quality and repeatability for small to medium production environments.

-

Fruugo ID:

462135479-972775446

-

EAN:

6091977151523