説明

Product description

Key features and benefits

Manufactured on metal lathes for precise, repeatable geometry and tight dimensional control.

Robust structure that supports mechanical stability and predictable mounting in assemblies.

Noninductive winding structure: minimizes parasitic inductance, improving performance in frequency, pulse, and fastswitching circuits.

Special square resistance element and protective coating: delivers consistent resistance distribution, stable thermal behavior, and improved surface protection against abrasion and contaminants.

tincontent tin–zinc alloy welding layer: enhances solderability and creates reliable, lowresistance joints with improved corrosion resistance.

Why this product solves problems

Reduces electrical noise and unwanted inductance in sensitive circuits because of the noninductive winding design.

Maintains resistance accuracy and thermal stability under load thanks to the square resistance element and coating.

Simplifies assembly and longterm reliability with a tincontent tin–zinc welding layer that bonds well to common solders and resists corrosion.

Precision manufacture on metal lathes and a stable structure ensure consistent fit and mechanical reliability in production and environments.

Function, materials, and compatibility

Function: precision resistive component with noninductive winding for lowinductance performance.

Materials: square resistance element with protective coating; welding layer of tin–zinc alloy with tin content for improved solderability and corrosion resistance.

Compatibility: intended for direct soldered assemblies and integration into PCBs, wirewound modules, or mechanical housings that accept standard soldering processes. Suitable for systems that require low inductance and stable resistance under thermal stress.

Typical applications

frequency or pulse circuits where low inductance is critical, such as RF front ends, pulse generators, and fastswitching power electronics.

Precision power supplies and currentsensing modules that require stable resistance and reliable solder joints.

Industrial equipment and assemblies produced or serviced on metal lathes where mechanical precision and robust structure are required.

Notes for designers and technicians

The noninductive winding structure is selected specifically to limit parasitic inductance—verify circuit requirements if inductance must be minimized.

The tin–zinc alloy welding layer contains a tin content to improve wetting and joint reliability; use standard soldering processes compatible with tinrich surfaces.

Inspect coating and mounting surfaces during assembly to ensure proper mechanical and thermal contact.

-

ブランド:

Unbranded

-

カテゴリー:

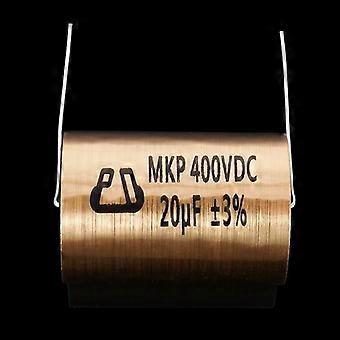

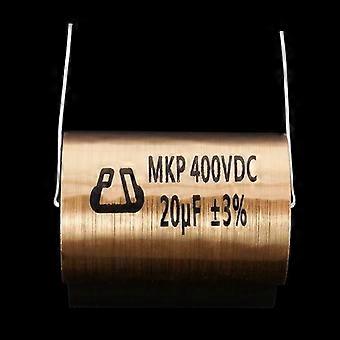

コンデンサ

-

Fruugo ID:

438573803-919340740

-

EAN:

6422352382476