説明

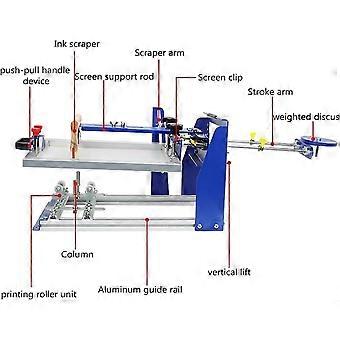

Manual Cylindrical Screen Printing Machine for Curved Bottles with Adjustable Rollers and Dual PushPull

Curved Screen Printer with Adjustable Rollers and Movable Base

Key benefits

Precise, repeatable positioning for curved surfaces: three independent roller sets allow accurate alignment and quick replacement to match different product geometries, reducing setup time and waste.

Flexible handling of many shapes: rollers can be mounted on the main frame or the accessory frame to support printing on cylindrical and conical products without extensive retooling.

Wide adjustment range for substrate size and height: the machine adapts to different parts and production needs, improving changeover speed and overall throughput.

Userfriendly left or right operation: the pushpull design and adjustable mounting parts support both lefthanded and righthanded workflows to fit operator preference and line layout.

Core features

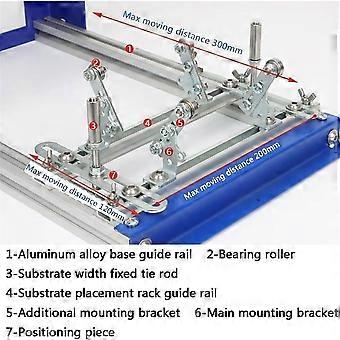

Roller configuration: 3 sets of rollers, precisely positionable and easily replaceable. Compatible with both main frame and accessory frame installations to accommodate a range of diameters and tapers.

Movable base rail: aluminum bar base rail provides 300 mm travel forward and backward for large positional adjustments during setup and printing.

Lateral adjustment: bearing mounting bracket secures directly in the aluminum bar mounting hole and can move up to 120 mm left or right to match substrate width.

Pushpull structure: left and right pushpull mechanical design with adjustable mounting parts. Suitable for lefthanded or righthanded operation.

Printing height: designed for a printing height of 160 mm.

Height adjustment: main screen frame moves up and down by loosening the rear connection screws, offering a 160 mm vertical adjustment range to align with substrate height and simplify conversions.

Materials and performance

Aluminum bar base rail for durable, lightweight movement and stable mounting.

Robust bearing mounting bracket for reliable lateral positioning under production conditions.

Designed for accurate, repeatable prints on curved and tapered surfaces, with fast roller swaps to support short runs and varied product lines.

Typical applications

Beverage and packaging industry: printing logos, measurement marks, or decorative bands on cylindrical and conical bottles, cans, and containers.

Promotional items and drinkware: direct screen printing on mugs, tumblers, and thermoses with curved or tapered profiles.

Industrial components: marking or coding cylindrical parts, tubes, and housings where precise registration and variable part geometry are required.

What this machine solves

Eliminates extensive retooling for different curved parts by providing configurable rollers and frames.

Reduces downtime with quick, tool style adjustments for lateral and vertical positioning.

Improves consistency across variable shapes thanks to precise roller positioning and stable mounting.

Specifications summary

Roller sets: 3, replaceable and adjustable

Base rail travel: 300 mm forward and backward

Lateral adjustment: up to 120 mm left or right

Printing height: 160 mm

Vertical adjustment range: 160 mm

This curved screen printer is suited for manufacturers and shops that need a flexible, dependable solution for printing on cylindrical and conical substrates while minimizing setup time and boosting production efficiency.

-

ブランド:

Unbranded

-

カテゴリー:

製造

-

Fruugo ID:

462949638-974165916

-

EAN:

6091977689767